- Construction Quality Assurance

- Special & Critical Inspections

- Geotechnical Inspection

- Soils Inspection

- Asphalt Inspection

- Concrete Inspection

- Masonry Inspection

- Welding, Bolting, NDT & Coatings Inspection

- Structural Integrity Inspection

- Passive Fire Code Inspections

- Mechanical, Electrical & Plumbing Inspections

- Electrical Inspections

- Architectural and General Building Construction Inspections

- Progress Inspections

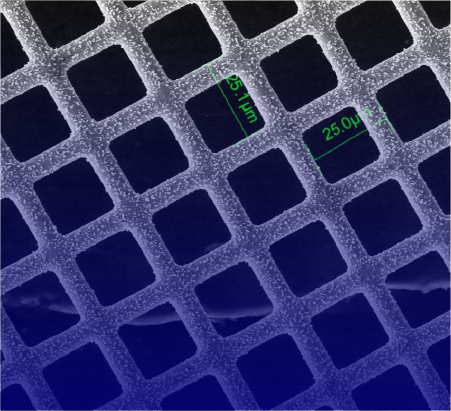

- Non-Destructive Testing

- Specialty Field Testing

- Construction Materials Testing

- Special & Critical Inspections

- Construction Inspection Management

Construction inspection management encompasses the coordination, supervision, and oversight of construction activities, ensuring that they align with approved plans, regulations, and industry best practices.

View More

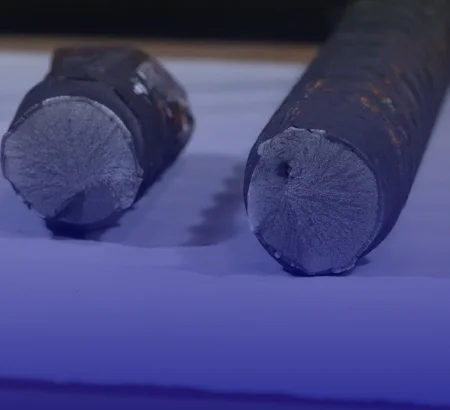

- Metallurgical Testing